Sea Walls

Mountain Grout Strong

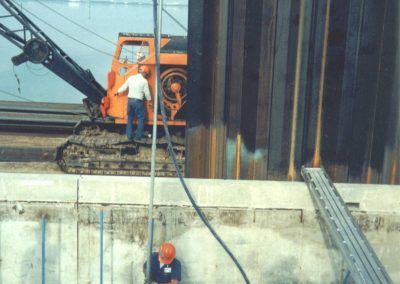

Green Mountain International is familiar with seawall repair dating back to the early ‘90s. GMI worked with the Army Corps of Engineers and South Florida Water Management to develop procedures and a specification to address failed joints in a concrete seawall (C-51 canal) near West Palm Beach, FL. The plan was to seal failed joints in the panels without excavating the soils to a depth of 10 feet.

The project was very successful by using grout pipes from grade and pumping the moisture cured polyurethane at each joint while retrieving the grout pipe (modified tremie method). Each project presents specific site conditions that prevent providing a comprehensive methodology that is all inclusive. At the C-51 project the contractor was able to work from grade which eliminated the need to dive the canal or work from the face of the panels drilling multiple holes in the section. Other seawall applications we’ve encountered over the years include stone block, Gabion baskets, wooden ties, fiberglass panels, and soldier pile configurations.

The ultimate goal is to deliver the polyurethane grout into the failure zone or void. The expanding polyurethane grout will react with the moisture present, expand and seal leak paths, fill voids and stabilize surrounding soils. If drilling is required there are 3 basic sizes of packers, 3/8”, ½” and 5/8”. The installer would use an appropriate size hammer drill with bit size corresponding to the packer size to be used. If large voids are present, an injection needle could be employed as one would be pumping at low pressure. This plan would be repeated as work is accomplished along the length of the wall.

Grout pipe placement in soils may be accomplished using a Rhino Driver or a 40 pound hammer, and can be water jetted or air jetted into place. Tube-a-manchettes (TAM’s) have also been employed where zone grouting is desirable. Green Mountain’s technical team (staff) is always available to discuss specifics and if desired to meet with the engineers, owners, representatives, and management staff. We offer on site visits to discuss specifics and answer questions, cover health/safety, and handling issues so that workers are well informed.

Equipment

- Mountain Grout Resin of Choice

- Mountain Grout Pump Flush

- Injection Pump

- Injection Pipes

- Clean 5-gallon buckets

- Paddle Mixer

- Personal Protective Equipment (PPE)

- Plastic Sheeting

- Tape

- Assorted Hand Tools

- Mountain Grout Ureclean Wipes or Rags

Get A Quote

GMI offers the best dealer pricing to qualified customers. Apply here.

SOCIAL